As we approach the 2019-2020 Winter, many thoughts should begin to turn toward raw material supplies of winter deicers. This is a good time to try to understand some of the dynamic forces that can affect supply and pricing of commodity products like road salt.

In over 40 years of winter product supply experience, I’ve not seen such wide variations in road salt pricing across the US as I am seeing right now.

One region is seeing prices fall while others are seeing prices rise and that is fairly unusual – and particularly so in the pre-season. When winter sets in and the demand switch for road salt is turned to the on position, it’s not surprising to see regions that are hardest hit begin to experience some pain in the supply and increase in price. The very definition of a commodity is that pricing is pretty even generally and moreover driven by supply and demand.

This year is very different with more fluid dynamics in play than a hydraulic system. I said fluid dynamics because largely, water is the force behind the lower prices as well as the higher prices in road salt this year.

In previous State of the Industry addresses, I wrote about the problems stemming from unrelenting rains and flooding in the US which have pushed rivers over their banks and caused silt to move into waterways and block them.

That has not improved.

In fact, it is worsening.

Good news first. For those along the East Coast, competition has continually increased with international sources of supply in road salt, which can go by many other names: rock salt, bulk ice control, and “salt.” As these new international sources have gained footholds in the US market, they are continually making improvements in ocean shipping, facilities, and ports. Many ports around the world have worked to upgrade channel depths to accommodate larger vessels with deeper drafts and larger cargo loads. In some cases, new ports and sources have been constructed and developed and we expect that will continue to apply downward price pressure along the East Coast. New sources in the Middle East and North Africa have been working to participate in the US market for over a decade with improving success. Many new sources have good quality road salt that will meet ASTM specifications for granulation and moisture. Establishing a position and supply of road salt is not as easy as one may think. Many have been the unfortunate victims of rip-offs by entering the world of importation and international shipping without the benefit of an expert “trail guide” only to encounter financial and quality problems with what they get… if anything. On the surface, that $16-per-ton offer from an email FOB in a Middle East or North African country may seem to be a great deal, but without understanding all the pieces of the puzzle needed to reach your location, you are doomed before you start.

More to the point, Egypt has been finding more and more channels into the US market. In the process they get better at understanding what the market needs in terms of quality and moisture. The Siwa Oasis region in the western desert of Egypt holds vast salt reserves – some good quality and some not-so-good. Having vast reserves and having the ability to mine, screen, and deliver it to a waiting vessel at a port are very different things. As the infrastructure to prepare salt for the US market has continually improved, these new sources have opened up a new port for export in Matruh which will shorten the distance from the mine region to the ship by over 50 percent. Typically, the port of Alexandria Egypt, which is 700 km away from Siwa, has been the only port of embarkation option for these sources, but now Matruh is just 300 Km north and that cuts the inland freight costs considerably. Brazil, South American, Mexican, and, Caribbean sources participate and many of these are new sources to the US market. With the East Coast US proximity and wide availability of deep-water ports up through the snow-belt, this will continue to confound the market with supply and competition. If you’re on the East coast and need salt, you should be able to get all you need provided you have properly qualified your source and quality. That’s the good news.

If you are in Heartland America in the snow belt, then you may be facing trouble on many fronts. First, the weather has all but wreaked havoc on the river systems with storm water volume. Remember that at the onset of this report I mentioned that water is key for both benefits and problems; it depends on where you are located. Because salt is one of the most inexpensive commodities on the planet, mining and transportation are generally 80 percent or more of the cost by the time it reaches end users. With regard to the central US, it is the largest expense in getting salt to market. There is not sufficient domestic North American production of road salt to supply the central US market. That market must have imported salt and that imported salt relies heavily on the waterways to move product to strategic piles. Along the Great Lakes, salt must move by barge or shallow draft “Laker” bulk carriers because most bulk ocean vessels cannot enter the lakes due to their draft depth requirements. This means salt moving by sea into the lakes requires either a shallow draft vessel or a stop at an intermediate location to then trans-load onto shallow draft vessels capable of moving across the lakes. The double handling and extra hands in the salt drive the costs up.

Domestic producers are very much aware of competitive pressures and, generally speaking, will match pricing to the lowest competitive offer. For example, a North American producer who is selling salt in the Baltimore market for $50 per ton may sell that same salt in the Midwest for a lot more since Baltimore is an active port and imported salt pressures down the price. But if the closest competitor in price is $90 per ton in Milwaukee, rest assured that the domestic producer will adjust accordingly.

Further stinging the salt market in the mid-west this year is the on-going high water in the Mississippi and adjacent waterway systems with some impassible. These rivers are vital transportation corridors for bulk commodities, and the high water has prevented barges and vessels from getting up and down the river. The back-up of bulk barges in NOLA (New Orleans) is significant. With the delays to get up river building up the back-logs, the barge rates have all but skyrocketed by as much as 250 percent with availability nearly nil. Again, those increased costs have to come from the market where they are sold. Moving inexpensive bulk commodities from point to point is always a game of transportation efficiency; and when that efficiency is impeded, the domino effect of price recovery takes off.

I think the East is fine and will get whatever they need absent another February 2015 weather pattern in which it was nearly impossible to keep up with demand driven by storms every 3 days for six plus weeks. The central US is a house of cards. They cannot get salt up the river and there is not sufficient domestic supply to cover demand if winter comes in. That is the big “if.” We cannot predict weather and there are a couple of scenarios by which things in the mid-west could get in trouble. If it were to snow early and hard, that will quickly deplete on-the-ground supplies with limited reloading. If snow arrives late and hard, the same situation will drive panic. If it doesn’t snow or is a mild winter, then all will be fine. Plan accordingly.

According to various sources, globally we consume about 80 million tons of road salt per year. Of that, the United States consumes about 25 percent in a heavy winter. Interestingly, Europe consumes just 7-8 million tons – or roughly ?rd of what the U.S. uses in the same time period. All of this despite Europe being twice the U.S. population with roughly the same-sized land mass and snowbelt.

How is it that we are using three times as much deicer with just half the population size?

If you ask 100 people in the snow business this question, you might get 50 different answers. However, here’s how I see it.

Tort law is No 1. Slip-and-fall lawsuits are expensive, with the average lawsuit settlement reaching over $100,000. That is everything from the “staged” fall in the supermarket to the person in leather dress shoes slamming their face on a snow-filled parking lot. The cost of settling these lawsuits far exceeds the cost of just blasting the surface with deicers. So, the prevailing mindset is, “If a little does a good job, more will do a better job.” We’ll soon learn why that mindset is often wrong.

The second issue is the advent of SUV and 4WD in the hands of people who shouldn’t be driving in snow. If you live in the Snowbelt, it’s likely you or a neighbor own a four-wheel or all-wheel drive vehicle. Those vehicles enable travel for a segment of our population that does not respect winter driving and thinks they don’t need to leave for work early on snow days – i.e. “The streets need to be black and wet!”

Adding insult to injury is that our climate is changing. We see more and more ice storms creeping North into the traditional Snowbelt. These ice storms consume 3-5 times the quantity of deicer than comparable snow storms. Fighting an ice storm is an all-chemical fight. In other words, a plow and shovel are useless for ice removal until that ice has been hit with chemical deicer first.

We’re seeing this problem all over the Southeast U.S. Many communities are now ramping their snow-fighting equipment following unexpected and sometimes catastrophic winter weather events. Take Atlanta and Dallas. In recent years, these communities were paralyzed by ice storms that closed down cities for days. Many of these disasters could’ve been avoided with more sufficient resources to manage wide-spread ice events. But now we’re seeing the aftermath, an over-reaction: too much willingness from affected communities to apply product during storms regardless of whether the conditions demand it.

Yes, it’s important to be prepared, and no one would argue that point. But now we need to take a closer look at how our behaviors might be creating bigger and more complicated problems.

Everything in life is a consequence for an action. Usually, the consequences are desired, such as melting away snow and ice so the surface is safely passable. However, when we increasingly slather our road surfaces with deicers, where does the run-off go? This is the adverse consequence of deicing use – because every pound of deicer purchased is disposed of back into the environment.

Think about that. Every pound purchased is then applied to the property of that purchaser – at which point the deicer either seeps into the ground, runs off with storm water, or if it’s chloride-based, reacts with steel to corrode bridges, vehicles, and electrical systems. Unfortunately, these potential adverse consequences for our transportation and infrastructure are just the tip of the iceberg.

Salt is sodium chloride. When sodium chloride seeps into ground water, aquifers, lakes, streams, and reservoirs, it contaminates fresh water and causes potential problems at many levels. Public and private well water supplies can experience elevated levels of sodium in the water, which is problematic for people with hypertension. In that case, it’s the sodium that’s the problem. But in other cases, it’s not the sodium; it’s the chloride. When salt runs off into fresh water surface bodies such as lakes and streams, it elevates the surface levels of chloride which may reach toxic levels for fish, plants, and other aquatic species.

As we already know, salt demand in the U.S. is exploding. And with this explosion comes an increase in new and often unproven global sources of salt entering the U.S. market. This isn’t always good. A New England region user who recently switched from a Chilean-sourced to North African-sourced salt provider later tested their product to find high levels of heavy metals. Unfortunately, those contaminants were high enough to break through the company’s storm water discharge permit threshold limits. The consequence: an EPA violation of a $250,000 fine, and a final warning that one more violation would close a nearly 100-year-old manufacturing business – thereby idling hundreds of employees. All of this from what should have been innocuous, routine winter ice control.

If we plan on preserving our private facilities, storm water management control centers, and environment, we need to be careful with new-to-market, unvetted global salt sources. It’s important all buyers of deicers and salt know exactly what they are buying, where it comes from, and that they demand for detailed certified breakdown of typical ingredients including contaminants and metals.

But it’s also just as important to recognize that this problem isn’t only limited to global markets. Recently, a U.S. source of magnesium chloride start showing detectable levels of poly chlorinated biphenyls (PCBs) in their liquid magnesium chloride deicer at a community in the Pacific northwest. PCBs are a major environment concern since they not only take hundreds of years break down, but they’re also carcinogenic. While the levels were relatively low, the fact is that PCB contamination in the Great Salt Lake carried over into product that was applied to roads in a state 800 miles away. That goes to show how widespread and interconnected these issues are, and understandably, why environmentalists and regulatory agencies are not enamored with polluting their highways and adjacent lands.

Moreover, areas with high population concentration and high use of deicing products are now seeing near-toxic levels of chlorides in fresh water; that is, toxic to people and fish. Flint, Mich., had lead problems that made major news headlines for over a year. Soon, we can expect to see high sodium levels and chloride levels in other communities threatening aquatic life and potable water purity. Is it possible that deicing usage might one day evoke the same public outcry as Flint did with its lead? If the environmental damage all falls back on the mismanagement of winter deicing operations, then the answer is yes.

These problems are not limited to road salt, but with upwards of 20 million tons of salt hitting the US environment every year. We need to look at all the products we use in winter deicing no differently than we would look at the fertilizers, herbicides, and pesticides used to manage agriculture and even right to what we put on our lawn. If you’re on a well, think about what you are applying to the surface of your property as it migrates down toward your water source. The deicing public is so focused on getting sidewalks, roadways, and surfaces free of snow to avoid slip-and-fall or crash potentials – they’re not thinking about the unintended problems from insanely high deicing use.

With increased attention on groundwater recharge, many property owners are now using porous pavement surfaces to enable groundwater recharge more readily. These porous surfaces facilitate groundwater recharge, but they also require more deicer to keep them unplugged from ice. We can quickly see how this might become counterproductive: save the surface for safe passage; destroy the groundwater with contaminants in the process. Keep in mind that when we pollute our drinking water sources, cleanup is incredibly expensive and difficult.

From what the state puts on our interstates and roads to what the homeowner buys at retail… all of it ends up back in our environment. There is little to no regulatory oversight, labeling requirements, or enforcement until after this type of pollution becomes the problem of the property owner. Once again, an adverse consequence.

No easy answers here. My viewpoint is that education should be first on our list. The motoring and traveling public must be more understanding during snow events. They cannot set the bar so high that we are slathering every horizontal surface with excessive deicers to allow for winter travel at dry pavement speeds. After that, we need to be better about informing property owners on the potential problems from heavy applications. We need to carefully respect that if we are adjacent to wetlands or on top of an aquifer, we must use much less product, or in some cases, a different product as to not potentially threaten those resources. If we make a broad, concerted effort to educate the market, it will benefit all of us. Finally, we need to use the best available practices and methods to reduce the amount of product we apply. This is so we meet needs and avoid over-applying – all while keeping our people and environment safe.

We need to advocate sensible deicing practices and help educate people who have no understanding of what we, snow fighters and related businesses, do. Most importantly, we need to encourage everyone to use less. Another 30 years of hitting our surfaces as we do now will find us saddled with obscene contamination cleanup costs… and that’s IF we even have the ability to clean up the mess.

Use less, educate more, and advocate for TORT reform.

While there is plenty of salt on this blue marble in space that we all live on, road salt availability in certain regions is showing early signs of supply and price problems as we enter the preseason this fall.

Coastal markets are generally well supplied from multiple sources globally. However, some interior regions of the US are already seeing signs of availability problems. Along with availability troubles come price increases so expect both in the affected regions. Much of this is the result of a significant uptick in transportation costs along with a series of events with domestic mines that triggered some delays and problems.

The relatively good news in supply will be the coastal snow belt of the Northeast United States. This region from North Carolina to the Canadian border has been a very competitive market for decades due to proximity to deep water ports where salt from as far away as Australia can arrive competitively against salt mined in North America. I’ve mentioned in previous State of the Salt addresses how ocean freight costs had plunged in recent years resulting from changes in ocean shipping and vessel size. Well, those days are now winding down and a new set of sea going vessel conditions are impacting road salt supplies.

Moving any bulk commodity product like road salt, require bulk containers whether they are dump trucks, rail cars or ships. Since one ship can haul enough salt to supply a small city for the entire winter and their costs are a fraction of rail and truck, water transportation is the main way in which salt tends to arrive where waterborne delivery is possible. Understanding some of these transportation nuances are important for all buyers of road salt as the salt itself does not see big swings in mining and harvesting costs, the delivery vehicle whether a rail car, dump truck or bulk ocean vessel, are seeing relatively big increases in costs. In my previous article, I wrote about the truck driver shortage in the U.S. Add ocean vessels to the mix now.

The largest dry bulk vessels are Cape Class vessels capable of carrying 150,000 DWT (dead weight tons) up to 450,000 DWT. Rates on dry bulk Cape Class ships are up nearly 100 percent over a year ago. Panamax vessels, the largest vessels that can transit the Panama Canal, average about 65,000 DWT and are seeing mostly flat rates, but the vessel availability is not great and particularly for salt movements. Supramax vessels can haul 50,000 tons are a common workhorse for salt and capable to transit the oceans and into deep water ports, but they cannot enter the Great Lakes or river system due to their deep draft. Surpramax vessels are available, but predominately only from Europe on a “European backhaul” basis. These facts are a key element to the next part of this report and explaining where trouble is starting to show up.

There are salt supply problems in the upper Midwest stemming from a series of events that combined into early trouble. Typically, the river system is busy in season (August to October) with moving grains from the grain belt down the Mississippi river by barges to NOLA (New Orleans) for shipment to overseas customers. That market right now is very robust, and the barge operators do not want to sit waiting for a salt ship to arrive to then transload into those same barges for a “backhaul” up the river to various ports. There is more revenue to be gleaned by turning right around and reloading grain because salt is always trying to move on the cheap. Why is this a problem? It’s a problem because those grain barges are going back up the river empty to catch the next downstream run without interruption because the prices and demand for grain is strong and road salt suppliers are unable to pay up $25 per ton more to go from New Orleans up to the grain belt. Therefore, even if a ship of salt does arrive in NOLA to then transload to barge service for river delivery, getting covered barges to haul that salt committed and booked is nearly impossible. Now they need to wait until grain season is over and hope to catch up-river barges provided an early freeze does not lock out the river and lake system for traffic.

We’ve been seeing early signs of trouble in the upper Midwest salt markets since July and that is deepening quickly. Most buyers have not realized just how serious supply is right now and by the time they do, it will likely be too late to do much about it. It is not out of the realm of possibility that the Midwest’s only option for salt may be from the coast by truck or rail if it snows and demand for what small amounts are currently available get quickly bought up. Add to that at least two prominent North American mines with flooding problems curbing production rates coupled with a three-month labor strike at the largest salt mine in the world in Goderich, Ontario, and you have a system that is behind, can’t catch up and has serious delivery problems as a result of the foregoing vessel market.

This does not mean that there is no hope, but what it means from my side of the desk is that if we want to move salt into the upper Midwest, our only option is to use seagoing vessels to move it into the St. Lawrence and Quebec, then unload onto dry land and book “Lakers” (lake service low draft barges/vessels) and then reload to ship on to the delivery point. All of that comes at a significant price increase due to multiple points of handling and travel. Each of these ports is often ILA controlled (International Longshoreman’s Association), where six-figure salaries are routine. Add to that the number of required union longshoremen to discharge or load a vessel and you can see how these costs quickly skyrocket. Options are narrow for getting salt to most places without involving a ship and longshoremen.

We believe that salt prices will continue to firm up and then begin rising as we move through the preseason window leading up to Nov. 1, which is the start of in-season prices for most suppliers. If it snows frequently in the upper Midwest markets, it will quickly deplete the inventories and then panic buying will quickly drive up prices and cut availability to nearly zero for private markets and make municipal markets very tight.

If you have not purchased and/or committed to the road salt that you expect you will need for this winter yet, you have very little time left to do that if any time at all. The early bird will get the only salt out there and then it will be a fight for tons anywhere you can get them. We do not expect to see any improvement in supply or prices on salt in the regions indicated at this time unless flooding in the affected mines is managed and stops, and the river and lakes do not freeze this year. If we have early and hard cold in the snow belt, all bets are off for supply of road salt. If on the other hand, it doesn’t snow, then none of this will much matter. Roll the salt dice accordingly.

Winter 2017-18 arrived late much like the past few winters. While many regions experienced significant and prolonged cold in December and early January, no appreciable amounts of snow in the population centers came during that cold stretch. While most apply salt during any snow event irrespective of whether it is truly needed or not, the demand volume knob was never turned beyond three on a scale to 10 this past winter. Yes, product did move, but in manageable amounts and at manageable velocity.

Velocity is the key.

While the supply side of the business can keep pace with intermittent or sporadic storms, problems arise when snowstorms come in back-to-back and on cold pavements. That weather pattern demands application of deicing products as the snow fighter shifts from a mechanical fight with plows and loaders to a chemical fight of salt and other products. If you want to see trouble coming, then pay close attention to weather patterns that stack up winter events in a tight delivery pattern as well as events that arrive late in the season when supplier stockpiles and inventories are intentionally driven down for economic considerations.

There is enough salt on this planet to fully treat a nuclear winter; however, not all of that is sitting in a stockpile around the corner. In fact, virtually all of it is in the ground and sea awaiting mining and harvesting. The supply side of the industry works hard to anticipate what will come for winter weather, then in a carefully orchestrated and choreographed plan they schedule stockpile initial filling, then fill the market for pre-season demand. Then the tricky part comes – when to re-load the stockpile and at what velocity. It usually takes a month or more to fill the market. Remember that fact when you need a complete reload in days. The system can’t meet that kind of intense demand on a big scale.

Manage risks.

Long-range weather forecasting and risk-taking are hallmarks of the decision tree when it comes to bringing in more product for bulk salt stockpiles and packaged deicer warehouses. It’s a big gamble and one in which there’s more than $100 million of products in play at any point in time. If we, the supply side, don’t have it in stock, we can’t sell it. It’s not hard to understand that component. However, the consumer market is averse to risk and refuses to purchase enough product to last the entire winter due to the uncertainty of the weather, so the burden of predicting the exact amount needed falls on the supply side. Generally, there’s disbelief, frustration, and anger directed towards suppliers when shortages occur, but they are caused by end users refusing to accept more risk.

Municipalities understand the risk and planning needs. Most have at least five to seven treatable events’ worth of inventory in stock to start the season. As soon as the first event is done, they initiate reloading, hoping to stay ahead of the curve if things turn tight. Private markets do not subscribe to this approach and generally have one to two storms of inventory, and then tend wait until they are sure that a storm is coming to call for a delivery.

That’s when trouble can begin. If they can hold on for a week or so before getting a delivery, the supply side can work them into a schedule and get product delivered in a manageable way. However, when everyone calls demanding immediate delivery and are told that cannot happen due to demand, panic tends to set in and the initial order for one is frequently doubled or tripled.

At no time in the history of man has doubling or tripling demand on an unavailable product helped to improve availability. It only worsens it … and likely exponentially. That’s the 50,000-foot view of the industry to help frame the conditions by which shortages occur.

Seeing shortages in April.

We generally declare our season over around Valentine’s Day. Historically, the market tries to run out inventories and will use whatever they have on hand to manage storms that tend to begin diminishing in frequency and intensity as we get closer to the start of summer. However, the past few years have been counter-cyclical and delivered much of the snow after January. It becomes even more difficult to determine what stockpile volumes will meet demand in the early spring adding another layer of unpredictability to the equation.

This year, we saw exactly that happen as the late season storms stimulated demand and, in some regions, created shortages as municipal supply trumps demand from the private markets. I’ve discussed the pitfalls for the salt suppliers in failing to supply municipal contracts as the penalty for supply failures are intensely costly and most suppliers will forsake spot market private supply to fulfill municipal. This is exacerbated by the late season where inventories are intentionally drawn down by all involved.

Understand price pressure.

While the overall demand for product was generally flat for an average winter, prices have been hammered down by a rush of new suppliers to the market that they believed was lucrative and short. In the spring of 2015 the market was very short. However, since then it has not been and now there is a bit of a glut of suppliers overall leading to continual downward price pressure.

That can only go for so long before the costs of holding inventory for extended periods coupled with on-going shortages of truck drivers and new DOT regulations on electronic data logs drive up the cost of transportation, forcing recovery of those costs. I do not see huge increases coming but I think we will see prices move up a bit in some markets more than others.

For example, the private market in the Chicago area jumped $10/ton in the spring as supplies ran out due to end of season syndrome. Salt and deicers are commodities like any other – price is driven by supply and demand, and demand was up and supply was down. It’s hard to predict the future, but I expect we’ll see some price recovery in bulk salt and possibly some bagged products as we move through the pre-season of winter 2018-2019.

Environmental pressure

This is a topic we all need to keep our eyes on closely. There has been a series of studies, reports and articles about rising levels of chlorides in North American fresh water. The rivers and lakes of the U.S. are beginning to show signs of the impact of what I will call excessive use of deicers.

This is a bit of a touchy subject, but we are routinely slathering surfaces with more deicing products than needed as fear of litigation drives that application. I am thinking that at some point, the EPA will likely regulate the business since every pound of deicing products purchased in the U.S. is “disposed of in the environment.”

While public safety has trumped other considerations, more attention is being directed at deicers for corrosion and chloride pollution. A recent article questioned if chlorides are the next phosphorus, referring to bans on phosphorus in detergents because of their role as a macro-nutrient to feed eutrophication – algae bloom in stagnant waters which chokes out eco-systems. There is real concern about the chloride impact in fresh waters so keep your eye on this topic; it may drive a whole new approach to chemical deicing and, at a minimum, it will advocate safe and careful applications of salt and allied products.

Generally, there is plenty of product available for the next season across the entire nation. I expect to see a little upwards price movement in certain regional markets – not all – but some regions will likely see an uptick in costs next season. As potential trade wars loom, their impact on premium deicers and salt may also play a role in increased costs. Environmental considerations and pollution from deicers will continue to grow as an issue and the industry will need to keep current with best available practices to ensure we are doing our part to minimize adverse impact from deicers.

Whenever I hear complaints that our products are dissolving cars and bridges, and ruining our waterways, I remind the complainer that if they would simply stay home until the storm is over and let the snow be cleared off and then have one application at the end, problem solved. The only reason we put any deicing products down is for public safety … there is no other reason.

Always remember that point and remind people who say we’re killing their [fill-in-the-blank] with our deicing products, that their insistence on driving in snow and not slowing down is what is causing that problem – not the people charged with treating the roads that the public demands be black and wet through the winter event from first to last flakes.

It is fall and the last week of September 2017 as I write this. Temperatures in many parts of the US snow belt this week have been in the 80s and 90s. How is that possible? An active hurricane season has caught the attention of many in the snow forecasting business. After 40 plus years in the snow business, I’ve come to the opinion that the long-range weather prognosticators are about as accurate as a blindfolded monkey with a dartboard.

With that said, I’ll get to the business at hand which the state of the salt or moreover the state of the deicing chemical business and what to expect as you enter the pre-season and fall. We’ve had two soft winters back to back and that can tend to lead to complacency in the end user market and severely high inventories on the supplier side. On the buyer, the “We can get what we need when it snows” mentality will prevail and while that is true for the start of the winter, it’s not necessarily a healthy and sustainable approach if we get into a protracted run of weather as we saw in the Northeast in the late winter of 2014-15 or what the Sierras saw last winter where we received an entire winter’s worth of snow in 42 days of non-stop weather events and the market ran dry on everything in those regions. Events like that will drain pipelines quickly and can trigger panic buying. At this point, the supply side is swimming in inventory on virtually everything, so it continues to be a buyer’s market.

Panic buying is exactly what happened as the following fall’s pre-season saw record demand which drove many to think the demand of the market was exponentially bigger than it really was. What followed that heavy inventory grab was two winters of warm pavement and little snow with lots of new suppliers from every reach of the planet. What little snow we did get, melted as soon as it was cleared so the need for deicers was anything but panic.

Late last season, the northeast got a little snow, but again, with no frost in the ground to speak of the need was minimal. So now you’re reading this article as you blindfold the monkey to let him then throw darts at the board of weather to determine what you might expect for snow this winter. My friend Malcolm Poole, who spent a lifetime in the salt business and is now retired, said of the salt business; “It’s two years of mediocrity, two years of sheer misery, and one year of incredible bliss and you only need to figure out what order those come in and where you are in that order”. I think Malcolm was dead right. Are we due for mediocrity, bliss, or misery? Give the blindfolded monkey the dart and find out.

Regarding “the state of the salt”, abundant inventories would be an understatement. Right now, you can pretty much get anything you want without delay. The supplier stockpile side of the business is about as full as it gets. While that may sound good, there could be some potential issues with that from the effects of long-term storage. Tarps get holes, water gets in the pile, and over time all deicing products are hygroscopic (absorb water) to some degree so understand that these products don’t necessarily store well long term. We’ve had to dispose of inventory that didn’t keep by making brines from it before it turned into bricks. Sometimes the options are less and disposal is the only option. In all cases, inventories of salt, calcium chloride, and magnesium chloride are at record levels but caveat emptor for quality for the reasons stated.

Be mindful of clearly understanding the quality of that inventory from a shelf life viewpoint. Moisture content is critical in deicing materials. The holes in the three-year-old tarp on the salt pile that let a little bit of rain and moisture wick into the pile may require a jackhammer to loosen up when temperatures are sustained at sub-freezing. If you are buying, know the quality of the product you’re getting. If you are looking at the salt and bagged products in your own inventory that you’ve been sitting on for two years, make sure that inventory is still usable because that’s not something you want to find out is lumped and hard when you are hit with an event and need product on the ground now.

Normally, I break out salt and premium deicers separately in this report but this time, they are all in the same boat; high inventory and buyer’s market…at least for now. Be careful where you commit your business for supply. Many of the companies that rushed the market a few years ago thinking it was always robust are now looking to get out and may have a great deal now, but they may not be there if old man winter comes back.

Lots of interest, misinformation, and buzz about going liquid. Liquids are not new. We sold our first liquid system in 1979 to the City of Haverhill MA; a community with lots of north facing sloped streets. They were challenged with cars that became toboggans in snow events and felt they could enhance their salt’s performance with liquid based off the Marquette Study which was released just a few years prior. Understanding how to use liquids, and when to use them is important.

Let’s talk about the three basic liquid products in the US:

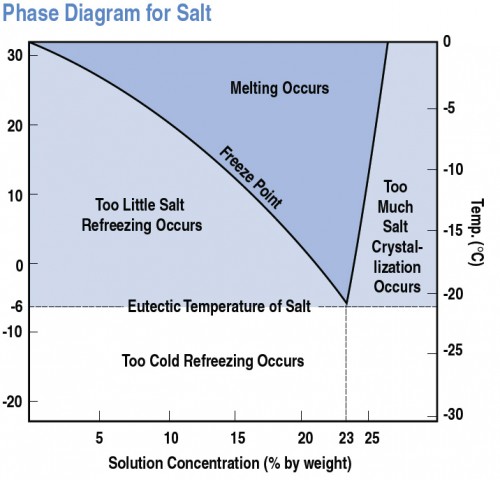

Salt Brine 23% NaCl – using a brine making machine or salt saturator, and a source of sodium chloride, on-site production of 23% NaCl is the target solution and common;

Liquid Calcium Chloride 32% CaCl2 – Most common commercial concentration and it is available in tank trucks and in small packages such as drums and totes in most regions. It is possible to manufacture calcium brines from dry product, but it’s difficult and requires a little know-how to make the 32% target solution;

Liquid Magnesium Chloride 30% MgCl2 – Most common commercial concentration and it is available in tank trucks and in small packages such as drums and totes in most regions. It is fairly easy to manufacture magnesium chloride brines from dry product, and that is done frequently where commercial bulk liquid is not readily available such as in remote regions.

There are too many “boutique” products on the market to begin to detail and discuss, but in nearly all of them, one of the liquids above is the base material.

We do not advocate applications of liquids alone for snow removal and deicing. In some instances, there are new technologies that apply an “oatmeal” type mix of high levels of salt brine and fine road salt for certain conditions. This methodology was developed in Europe and is now finding its way into some US states with specially built application trucks. In those instances, salt brine tends to lend an extra buffer of safety in the use of salt brine versus calcium chloride or magnesium chloride which can quickly make a surface very slick when over-applied or applied incorrectly. If you are interested in learning more on this, you might read the Vermont Agency of Transportation’s report on their work from 2008/2009. Understand also that the road salt used in this process is much smaller granulation and a specialty product – but the “oatmeal” application system performed very well once balanced. (For more, enter http://bit.ly/2ybVM1h into your browser)

Liquids are now over 40 years in the snow and ice market and they are here to stay. However, liquids alone will never replace dry product in the snow belt. Salt, and packaged deicers are at their highest pre-season inventory levels in years, however be wise about not expecting that inventory to be quickly replenished if weather causes a “run-on-the-bank” of those inventories. Suppliers are still stinging from a lack of snow and once that product is sold, they will be cautious to reload inventory the later into the winter it gets. This could lead to late winter shortages if that happens. In one case, a salt importer is suing 48 communities in one East Coast state for not taking their winter estimate of salt because it didn’t snow. Be mindful of the condition of products offered due to the long-term storage ramifications.

“Nothing is as easy as it looks” the weather prognosticators lament after last year’s abysmally missed winter forecasts.

All the experts called for another brutal winter and it was anything but brutal.

So, what does that mean for deicing products in North America? It means that the market is long and it’s a buyer’s market; whatever products you need or want, are plentiful and lower in cost. That’s the good news. However, we are also saying “caveat emptor” – Latin for “buyer beware.” The reason buyers need to be extra careful right now is multifaceted; but in simple terms, a perfect storm of market conditions in the preceding two winters attracted a lot of attention.

The perfect storm consisted of a strong U.S. dollar, weak winters in Europe, weak oil drilling, weak ocean freight, and a sudden one-year spike of opportunity driven by the intense frequency of storms in North America two years ago. That all lead to a rush to the market of new and unproven players.

The salt shortages in February of 2015 illuminated an underserved market. That short market was more the result of unexpected intense velocity than actual shortages. Moreover, when we have 125 inches of snow in five weeks in the Northeast, the velocity of demand is such that no suppliers could ever meet all of that demand, and many end-users did not understand that it was a temporary condition. It is impossible to store an entire winter’s worth of inventory and then deliver that all in one month.

The oil and gas industries use many of the same materials that the deicing industry uses: salt, calcium chloride, and magnesium chloride. With the collapse of oil prices, drill bits stopped and so did the demand for these materials which we use in winter maintenance. Adding to the allure of an underserved market is the strength of the U.S. dollar against all foreign currencies. Companies servicing the oil drilling markets that had collapsed now saw hope for recovery in snow and ice control after hearing of high prices and demand that was not being serviced…or so they thought. While those industries use the same chemicals, they are in different forms not suitable for snow and ice unless you like spreading powders. Adding to this imbalance of economics is the simultaneous collapse of bulk ocean shipping from over-supply. Bulk ships that haul bulk commodities including salt from production points around the world were being parked with reduced demand.

The quality, reliability, safety of production, and many factors that are part and parcel of ISO 9000-certified production are not at all the case in other countries. It is not as simple as saying “I’d like to buy a ship of salt” with no experience in the market, but that is exactly what happened last year as everyone hoped to cash in big on another hard winter with high prices. That winter never came so these tons sit outside, uncovered in many cases, and are not of the quality standards for gradation, moisture, and purity that many may expect.

What does this mean to the buyer? It means you may have a frozen solid pile of salt when you go to use it in sub-freezing temperatures, and it may also mean reduced performance when it is useable from the actual quality versus expected quality. If the temperatures plunge and that bargain buy on evaporated salt looked good at 40F, it’s going to not be the great experience you hoped at 5F as it needs jackhammers to move.

We also see some products showing up in the market which are low quality when produced and some are just old inventory that has been sitting around since the spring of 2015 waiting for a season to move them. As the market goes out to explore buying opportunities for the pre-season, it is essential to have a firm understanding of the manufacturer’s warranty on the condition of the product and to get that in writing. Additionally, with the rush of new companies from overseas, understand that if you have a quality or product performance problem that results in a catastrophe, you need to be comfortable being the first and possibly only line of defense legally for the problem you didn’t create in the product your company sold.

For example, we provide certificates of insurance to customers routinely showing our $4 million of product’s liability insurance in addition to the routine coverages of general liability and worker’s compensation. Products liability is not “general liability,” which covers only claims within our property. Rather, products liability insurance covers product failures and claims against the product. We constantly see certificates from companies that have liability insurance, but not products liability which is a separate and delineated line item on certificates. We represent companies with a substantial physical footprint and presence in the U.S, so there is a supply chain for any potential litigation help within the U.S. borders for claims. Try filing a slip-and-fall lawsuit against a seller with a laptop, cellphone, and leased car whose production is in a third world country and let us know how that works for you.

The market is long on every product offered. It has been a long dry spell from the producer’s viewpoint for snow and ice demand. We’ve fortified inventories to the ceiling and are awaiting the arrival of winter weather and the corresponding demand. End users and applicators of snow and ice products need to understand that if we see another high velocity winter like was saw in 2015, we will be back in the shortages again and at that point, the lower quality products will all rush the market; that is when you might find exposures to trouble. High moisture content in salt, calcium chloride, magnesium chloride, and blends from product sitting outside and uncovered in many cases for the past 20 months will either cause caking and hardening which means lumps that you have to hand remove from application equipment to keep going, or worse frozen salt piles that are more like a truckload of cantaloupes than free-flowing road salt.

Do your homework on the products. Demand a certified full chemical analysis on any product and don’t accept verbal assurances without a written certification. If the corrosion proof CMA deicer you purchased destroys $100,000 of new concrete, make sure you are not all alone paying for that product liability problem out of your pocket.

“Here we go again”

That phrase can apply to a lot of things in life; positive things, negative things, but it always implies that it’s something with which you are familiar.

So when I open this edition of my State of the Salt Address with that phrase, you know it’s not going to contain a surprise and it does not.

We’re far from out of the woods on winter chemical supply balance across the board. Pretty much everything is challenged to meet demand.

I’ll start with the star of the show, bulk rock salt.

Last winter’s late arrival and unrelenting pounding into the population centers of the Central and Eastern US sucked up salt at record amounts in those markets.

Not all markets were pounded with record snowfalls like Boston and New England, but pretty much everyone had a taste of winter’s wrath.

Weather

I’ve always been of the opinion that you can take long range weather forecasting with a grain of salt, meaning I put little to no stock in weather forecasts that tell me we are going to have severe weather in six months. They have trouble telling us what will happen tomorrow accurately so how can predictions about six months from now have any true degree of reliability? That is my opinion and I’m sure others see it differently including the people who are paid to provide the information.

With that premise, then believe any of the following you like:

Fifteen years until the start next mini-ice age: OK, this one I actually tend to lean more towards because they are basing that prediction on sun spots and those of you who read my newsletters know that I believe the sun is the largest single weather effect we have on earth’s weather.

Another brutally winter is coming in 2015/2016 – worse than last year. Yes, I certainly like the sound of this, but will throw darts with a blindfold and then average the two data points. Personally, after 42 years in the snow and ice chemical business, I can only remember one time when we had three heavy snow and cold winters in a row.

Powerful super El Nino will bury snow belt cities. Well the super el nino is setting up, but whether or not the jet stream cooperates with arctic air to let all that moisture land as snow remains to be seen.

So it should be no surprise that salt stockpiles were cleaned down to the floors in the suppliers, the municipalities, and the consumers.

While we were trying to reload those stockpiles in the late spring months of April through June, nearly all of those tons went right out the door to “refill and top off” municipal contracts where prices were all but guaranteed to rise in the next rounds of bidding.

Prices on bulk road salt are up in the shortest supply markets and only slightly up in markets where last year’s big price increases held.

It was late June before the salt industry started to build local stockpile inventories in earnest. The record warm winter in Europe coupled with a record solar salt harvest in China has put salt in a supply glut in the rest of the world therefore freeing up those tons to attack the US market. In addition, while ocean container freight rates have climbed in nearly obscene ways, bulk ocean rates are the lowest they’ve been in a decade which further enabled distant supplies to reach the US shores. Adding to this scenario is a very strong US dollar right now. As I write this, one US dollar is equal to $1.31 CDN, and 0.91 Euro where a year ago it was $1.06 CDN and $0.73 Euro.

The combinations of international currency exchange rates, low bulk ocean shipping rates, and warm winters in the rest of the world have combined in a perfect storm of TEMPORARY opportunity for foreign supplies. There are long-term reliable supply options and there are short term supply options.

If you choose to play in this arena, make sure you know the difference because the companies you compete with today with your new source may well become your only option when currency and weather normalizes and these supplies dry up and can’t leave their own shores. That’s the big picture globally on supply.

It’s straight forward, but many are lulled into a sense of false security by the thought of huge price differentials in the costs to buy and the current market to sell. My friend Malcolm Poole spent a lifetime in the salt business and he said to me a simple phrase that I’ve been careful to remember; “you want to collect the crumbs of opportunity the elephant drops but you must always be careful to not become toe jam on the elephant” Four companies dominate the US bulk salt supply. They are the elephants and newer suppliers may well find themselves under the foot of these elephants when things normalize.

I think normalizing is the key to all of this. What we are in right now is a temporary situation that is abnormal in weather, depleting supplies, and periods of intense demand. Salt is the most abundant commodity on earth, but it’s hard to store enough in any market to satisfy peak record demand times. Keep your relationship with the suppliers you’ve known for years even if it is a very reduced position. Burn that bridge now and when things flip the other way, you’ll look back with regret when you can’t get anything because currency and other conditions have taken the new supply players away.

Calcium chloride is sold in liquid and dry forms. Like salt, it has many uses from controlling dust in summer, to snow and ice in the winter, in brine systems for refrigeration and skating rinks, and more to my point in oil.

Calcium chloride is used extensively in energy markets as a completion fluid in oil drilling and as part of a formula for hydrofracking in gas markets. Those markets are currently nearly idle due to low cost oil from OPEC.

When oil production suddenly stopped in Alberta, Dakotas, and in the Permian Basin of Texas last winter, many tens of thousands of tons of calcium chloride were freed up for winter markets. And, that was global so there is plenty of calcium chloride available right now from all sources.

June 1st OSHA GHS compliance

This topic is well off the radar of most reading this article. It shouldn’t be. While it has relatively minor impact on bulk salt it could, repeat could, have an effect on packaged products. On June 1st, OSHA regulations changed for packaging of affected materials and for document management on all materials. For example, many are aware that “MSDS” is now a thing of the past as we have a new Global Harmonized System Safety Data Sheet — or called simply; “SDS”.

OSHA’s new regulations are confusing and while some believe that consumer product packaging impacts 50 lb. and down packages and supersedes OSHA rules for GHS, the fact is absolute answers are hard to come by from anyone including OSHA. We’ve gotten different answers to this question each time we’ve asked it.

On the SDS change, there is no question that new regulations’ compliance for business is in full force and effect so make sure you have updated all SDS for each product you have to the post June 1 GHS compliant safety data sheets. On labeling, the new regulations focus on hazard classes for each product; and most deicers are non-hazardous, so it is unlikely to have a big impact initially unless there is a precedent set that a bag of salt must contain all the safety pictograms, signal word, and hazard warnings for various potential exposure issues.

This is not going to last. Any number of scenarios could and likely will occur such as the calcium chloride equivalent of a run-on-the-bank where sudden mega orders deplete supplies and cause shortages. That happened from about this time last year right through the winter.

While we have new supplies from Russia, China, India, and Europe hitting the US shores right now, think about those currency exchange rates and price of a barrel of oil to know when it’s time to expect supply problems. OXY, the premier US manufacturer of calcium chloride is on open order right now; you can get all you want and following a totally empty pipeline from last winter, most people are not thinking about buying ice melters in the heat of summer but that is exactly what you should be doing. The first frost will change psyches and that’s when we usually see a run-on-the-bank for supply which in turn triggers order control and no product available. The early bird will get all the worms in calcium chloride in our view.

Magnesium chloride sold in liquid and dry forms. Like calcium chloride, magnesium chloride has many uses from dust control, to snow and ice control, completion fluids for oil drilling and in hydrofracking. Unlike calcium chloride, magnesium chloride continues to be in a severe shortage.

The winter depleted all the stocks of magnesium chloride and two new market uses for this product are pulling significant quantities in a market that is severely oversold. Adding to this pain was a labor strike at Dead Sea Works who are the prime supplier of dry magnesium chloride pellets and flake to the US market.

While that strike lasted 4 months, the timing couldn’t have been any worse for the US market that uses MAG products. It came at the peak of record winter demand and never recovered. Their plant is still not fully operational, and while some of their MAG product is beginning to dribble in, demand outstrips supply by a wide margin. It will be a very challenging year for Magnesium Chloride dry products, and, at the present time, liquids seem to be mostly unaffected for supply.

Blended deicers products are generally salt and something else. The something else component may be in quantities that are meaningful and, more often than not, amounts that are either insignificant or non-existent.

With the premium product shortages of calcium chloride and magnesium chloride, the fortified blended products with meaningful amounts of premium deicer are going to be much less available in the market this year. I’ve always advocated demanding a full disclosure of ingredients from the supplier and manufacturer for anyone using any product. What is to hide? A legitimate blend that has at least 3 percent, and as high as 20 percent magnesium chloride or calcium chloride will provide true performance and will be an excellent back-up option while pure premium packaged ice melters are in tight supplies or unavailable.

This is not a secret science nor is it something that has any reason to not disclose; they are simple chloride ice melters. Many claims of added premium ingredients in blends are false, and the only way in which to know for sure is to demand a certified breakdown of ingredients by percent weight. Any supplier who refuses to provide such evidence of what you are buying is not only in violation of federal and state right-to-know laws; it is just ethically wrong.

Be careful to know what exactly you are buying in blended products considering these shortages and don’t get tricked into buying dyed rock salt for three times value. Demand the breakdown information and a certified analysis from your supplier and if they refuse, ask what do they have to hide?

We provide legitimate blends and blends may be the only option for many this coming winter. We immediately took action last March when Dead Sea Works magnesium chloride facility went on labor strike to secure sufficient tons of magnesium chloride in order to build our TruMelt and ClearPath Winter Wizard inventories over the summer to be ready to ship these premium blends for the coming winter. Many waited until summer to try to find premium ingredient supplies only to learn there are none. Caveat emptor.

It’s 15° F and snowing and it feels like the salt you just put down took a vacation.

Salt is the least expensive and most abundant deicing material on the market. On a cost-benefit analysis salt is difficult to beat when considered against alternative materials. The performance of salt in its practical operating range above 25° F makes it an extremely cost effective solution in that temperature range. While materials such as calcium chloride and magnesium chloride are very effective to temperatures well below zero, these materials are considerably more expensive than road salt or rock salt. However, in temperatures below 25° F, the effectiveness of salt decreases dramatically.

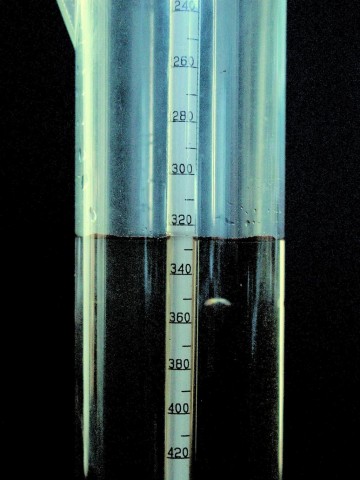

A reference from the Snowfighter’s Handbook published by the Salt Institute shows just how quickly salt’s effectiveness plunges with temperature:

| POUNDS OF ICE MELTED | PER POUND OF SALT |

| Temperature Degrees F | One Pound of Sodium Chloride (Salt) |

| 30 | 46.3 lb of ice |

| 20 | 8.6 lb of ice |

| 15 | 6.3 lb of ice |

| 10 | 4.9 lb of ice |

| 5 | 4.1 lb of ice |

| 0 | 3.7 lb of ice |

| -6 | 3.2 lb of ice |

Most experienced snowfighters know that the colder it gets, the more difficult it is to get salt to brine (form a solution from melting snow/ice), but few realize just how dramatically that performance drops off below 25°F.

At 30° F, 1 lb of salt will melt 46 lbs of ice. However, at 15° F that performance will drop by over 86%! Yes it is only about 13% as effective at 15 ° as it is at 30°. So what can be done about that?

The Marquette University Salt Study showed that pre-wetting salt, using a liquid brine to enhance and “jump-start” the brining process with snow, improved its performance at low temperatures. Pre-wetting has many advantages, but the costs of liquid application systems are expensive, require maintenance, and of course you have to have the liquid to fill the saddle tanks on the trucks.

In the 1990’s a series of boutique additives began to emerge that allowed a stockpile of salt to be treated with a performance liquid that had been modified with an additive that prevented the liquid from activating in order to enhance melting performance when applied at low temperatures.

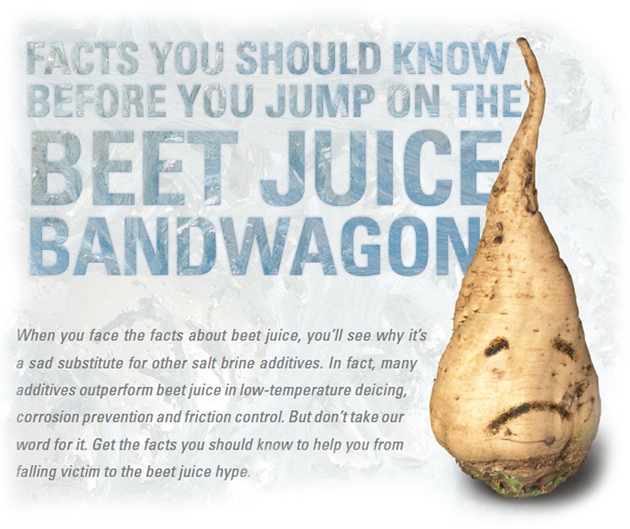

The first product to the market for this was called IceBan and it was a distillation or brewing waste product. Many will remember the “beer smell” and brown liquids that were promoted in the 90s under the brand. The original IceBan (and Magic) patents for using the brewer’s condensed solubles have now expired and with the explosion of microbreweries, many municipal snowfighters are sourcing some of these liquid additives locally for free or nominal costs and adding them to their liquids and snow fighting arsenal.

We now have a way to envelop or encapsulate the salt particle with a premium chloride liquid such as calcium chloride or magnesium chloride. When that particle hits the pavement, the premium chloride has a lower temperature performance and it will synergize the brining of the salt particle much like putting jumper cables on a dead or weak battery. It gets just enough kick to help the salt to start forming a brine thus increasing its effectiveness.

So how do you get performance at lower temperatures without the cost of using all calcium chloride or magnesium chloride? You use our treated or pre-wetted salt, commonly referred to as Magic Salt or treated salt. We encapsulate each particle with a patented mixture of molasses and magnesium chloride which together will provide the advantages of pre-wetting without activating until it is applied to the surface and exposed to snow and ice.

To learn more about our performance products and how to maximize the performance of the salt you use, give us a call at 508-520-3900 or send us a note on our Contact page.

THE PERFECT STORM – An industry still recovering

As Yogi Berra famously said; “it ain’t over until it’s over”.

With regards to the painful salt and premium deicer supply shortages that began last December, they are not over. On-going challenging resupply scenarios continue to impact the market and those who have been complacent will be stunned when they find there is little or no road salt available right now. It is, for the most part at least, a predominately regional problem; some areas will have barely ample supplies and some will have painfully short supplies.

The deicer industry overall is not on solid ground at all and significant problems continue with the supply chain logistics across all product groups and road salt in particular. While Europe saw their warmest winter, in 2013/2014 North America saw a very cold, long, and hard winter not experienced in decades which drained all supplies. NOAA, the government weather service recorded the coldest winter ever on record for much of the US. The details of the then impending road salt supply collapse were published in my December 2013 State of the Salt newsletter, and recapped again in the spring newsletter. Many of our customers and partners took heed and acted quickly to protect themselves as our stockpiles were nearly out. Early commitments on the heels of last winter had us delivering next winter’s supplies before the ‘13/’14 winter was even over and we have not had any break on re-supply with strong unrelenting demand from the market. As we enter August, people will be shocked to find that they may not be able to get anything.

ROAD SALT

The signs of continuing trouble are now confirmed with statewide contracts finding no bidders interested in committing to supply beyond spot market and what we have today. Two prominent states went out to bid for over one million tons of salt and did not get one offer or taker where they’d typically have half dozen or more. They were not prepared for that and are now scrambling to determine how to manage supplying their states with salt. Jefferson County IL also found no bidders for their annual supply contract offered in July, and took the only offer they had at twice the price for just 600 tons. Their costs jumped from $60/ton to $117/ton and this scenario is now repeating itself in regions all over the country. Throughout the Midwest, road salt prices are ranging as high $140/ton if you can even get anyone to commit to supply. When statewide bids go off with no offers, that is a good indication things are so oversold that the producers are keeping their options open while they run wide open to fill their existing commitments. Pricing will be impossible to predict because there is little or no product available on the open market right now.

In the central US, road salt supplies are in dire straits and will not improve. The Western US, while not huge users of road salt relative to other regions, will feel the supply pinch as the producers west of the Rockies struggle to service their customers east of the divide and take advantage of a high priced market. In the South and Eastern US we do not yet know if that string of ships arriving from places as far away as the Chile and Morocco will have enough product to refill a totally drained pipeline and supply chain. The entire road salt supply system was broom clean nationwide at the end of the winter. Now, we are still struggling to recover in the midst of record demand, high fuel costs, gummed up and slow rail movements, and, high water disrupted river traffic, all have combed into the perfect storm to hamper restocking efforts.

Adding to the re-supply pain for the salt industry overall was the fact that nearly all the tons produced through the spring that would normally be intended for stockpile rebuilding ended up going into still open municipal contracts and filling up their salt sheds on last year’s price. Speaking of price understand that salt and premium deicers are commodities and accordingly they will fluctuate in pricing based on supply and demand. Right now, supplies are short – very short – and the demand is high – very high – so do the math yourself. They key is not how much does it cost, the key is can you get it now, and more importantly in winter if you need to reload?

Road salt mining operations and premium deicer production have been running at full capacity. Europe’s warm winter made supplies held for Europe available to the North American market, but these are generally a different specification (much finer gradation) and not suitable for the application methods of the North American market. The road salt shortage is more a logistical problem and less a resource problem. There’s plenty of salt in the ground and in the world, but refilling a system with substantially more than the entire system has taken ever before is proving to be stiff challenge. Many southern US cities whose snow normally melted on contact, were paralyzed by a series of polar vortex deep freeze snowfalls and they now are attempting to build stockpiles they never had before; further pinching the system. Adding to the challenge is the fact some of the US salt mines near population centers that have been in operation for more than 50 years are manmade caverns in the earth and some of these are in a state of convergence. That is serious business and has caused mines to suddenly close permanently. One of the more sensational salt mine collapses happened November 20th 1980 in LA where a mine operating since 1918 collapsed at Lake Peigneur and the video documentary story of that is worth viewing if you are interested. The point is that while worldwide we have plenty of salt, regionally, we may see additional problems as mines relied upon for decades might suddenly go off line; it does happen.

PREMIUM DEICERS

Calcium chloride and magnesium chloride products are no better off than road salt at this point. All producers worldwide are essentially completely sold out resulting from the high costs of fuel and energy where those products play critical roles in the energy development and harvesting. OXY, the sole US manufacturer of calcium chloride pellets, continues order management and allocation with their Peladow calcium chloride pellet product at least through year end. Flake calcium chloride, at least as of the time I’m writing this, is still available without limit, but that will surely change as panic buying spikes demand. Magnesium chloride producers worldwide are also sold out completely. The Dead Sea magnesium chloride production has been reduced for unknown reasons, and logistics are disrupted. DSW’s MAG Pellets are also on very snug order control indefinitely. Premium deicer pellets are preferred in packaged products and they are going to be in very short supply for the foreseeable future. You will have to be understanding and willing to work with alternatives until these challenges and problems are able to sort themselves through. We have options but you need to talk to your sales representative about what is available in premium products.

Don’t be misled by any claims of ample supplies of these materials; they are in extremely tight supply and any weather related sudden pull will extinguish the hand to mouth inventories we’re trying desperately to build up but cannot due to unrelenting demand. The best products are always the first ones to go so know that if you’ve not made commitments on premium products by now, you’re in more trouble than you might think.

WEATHER

I’ve often pondered that if I could predict the weather accurately I could rule the world. I don’t put a lot of stock in long range forecasts, and based on my own experience with short range forecasting, they are not a whole lot better for anything other than general trends. With that said, most if not all of the weather prognosticators are lining up and singing the same tune albeit not necessarily in harmony; it’s going to be another challenging winter with anything but warm weather in the snowbelts. Matthew Holliday’s First Hand Weather suggests a repeat of last year. Joe Bastardi, who has been frighteningly accurate in most of his predictions, also is calling it above average snowfall for the snow belts, and goes so far as to predict VA, NC, TN, WV, and MD as winter battle zones. For my hometown of Boston and the northeast US, and for the Great Lakes region, he’s calling it above average snow and below average temps. Again, from my perspective, long range forecasting like this is a guessing game with complex computer modeling and I personally have found a dart board to be equally accurate. There is a lot of chatter about a strong el Niño and that has in the past resulted in above average snowfall for most of the US snowbelt. For what it’s worth, my dart board concurs with the weather prognosticators.

SUMMARY

I think there’s just no question that a lot of people will be left short and without ample supplies so the weather will be the key. Use professional and other weather forecasting at your own peril. A warmer ocean should mean the snow belt population centers of the East Coast will be slow to start, but that concept is in sharp contrast to what the “expert” forecasters are saying. Road salt will not recover this year if there is any snow; there is just no question about that from our viewpoint. Again, remember that the challenges in road salt are largely regional, with heartland America far and away in the worst shape, however the snowbelts and population centers of the East Coast and Northeast are also not entirely safe. We are loading our warehouses with packaged melters and building our bulk salt and treated salt stockpiles now with products, however product is going out about as fast as its coming in so please be patient and allow us time to cover everyone’s needs.

Since I opened with a quote I’ll close this edition of the State of the Salt Newsletter with a quote: “Cheer up, things will get worse”

Robert S. English

President

By Rob English

When spring arrives, the snow fighter faces a large workload of preparing the winter maintenance equipment for a long summer’s nap, cleaning up any winter kill, and, responding to a series of questions and complaints from the property owners on the efforts put forth over the winter months. Inevitably, the topic of concrete damage will come up. Concrete damage from winter snow operations generally comes in two forms; impact/scrape damage from mechanical contact such as loader buckets and snow pusher edges colliding with curbing or scraping the surface, and, spalling damage.

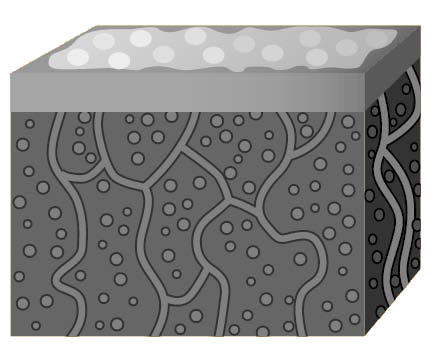

Spalling damage is common in concrete and most of the time it is caused by substandard concrete. While the concrete in the truck that is poured in place is usually within specification, the art of properly installing, floating, and burping the air from the concrete varies widely amongst installers. When we see spalling damage, most often it presents as a loss of the top surface area down to the aggregate as shown in the photo below. Sometimes it looks like someone took a shotgun to the sidewalk and lots of small “blast craters” appear, and sometimes it is widespread and wholesale failure of the surface.

To understand how spalling damage happens, first know that it is generally NOT a chemical attack. In some rare cases such as high dolomite concrete mixes, there is evidence to suggest that those concrete mixes may be susceptible to magnesium compounds of all types whether they are fertilizers or ice melter. But that is the exception by far and not the rule and it appears to be limited only to a small area of Iowa based on just one report. Far more common is freeze:thaw related spalling damage whereby brines formed by melted snow enter the air pockets of the concrete and refreeze when temperatures drop below the freezing point of the brine overnight. When water or brines freeze, just like the ice cubes in your refrigerator’s freezer tray, they expand. If they are trapped inside an air pocket void and expand when they freeze, then those brines will displace the concrete shell holding them back.

I was called in to analyze a complaint on spalling damage to a concrete floor that was claimed to be from deicers a number of years ago in the Baltimore, MD area. I went to look at the site and the damage that was evident was typical spalling damage, but what was curious about it was that the spalling failure was very deep and crater like; almost like a little volcano. The investigation was involved and included a number of parties and when we finally found the root cause, it was pretty stunning: The concrete company that made the concrete had a bulk pneumatic trailer that they used to pick up bulk concrete. They had made a deal with a local limestone company to haul bulk quicklime to a site near where they picked up concrete and the same truck would haul quicklime up and concrete back without any washout. The concrete was contaminated with small bits of quicklime which attacked the concrete chemically and caused deep pock spalling. That is a rare incidence of chemical derived spalling but as snow-fighters it is also important to remember that while our DNA might be at the crime scene, we are not always the one who caused the problem.

Some of the things that the snow removal contractor should do is to become alert to recognizing places that may be susceptible to spalling before the winter even begins and point them out to the property owner in advance. Areas of new concrete, and many of the newer high end colored stamped concrete surfaces all can be more susceptible to damage than well established concrete.

In addition to areas of new concrete, be vigilant to recognize subtle signs of failure underway which may be exacerbated by the snow-fighter’s work with deicers such as what you see in the photo below:

On first glance, these steps might appear to be solid, and they should be since they are well over 20 years old. However if you look closely you can see streaks of rust. Concrete doesn’t normally show rust unless the reinforcing bar and concrete matrix are failing; and that is exactly what is happening with these steps.

Right now they are stable, but if you look closely at them you will see a significant crack running the length of the steps that has opened the concrete below to accept all the melted brine from winter maintenance and it is just waiting to fill up with fluid, refreeze, and blow the front corner of these steps off. As the snow removal contractor is charged with keeping these clear, he will also be blamed for the failure that is immanent.

Spalling damage comes in a few forms; as small pock marks that look like someone took a shotgun to the concrete surface, and sometimes as widespread wholesale destruction of as section of the entire surface. Your concrete installer doesn’t want to hear that it’s his problem, which in my professional opinion it actually is most of the time. He doesn’t want the liability of replacement saddled upon him, so normally the source of concrete damage becomes the commercial equivalent of the children’s game “hot potato” where the buck is passed quickly in an attempt to dodge responsibility for the problem. The image below shows spalling failure in a structural concrete matrix with re-bar first taking on brines to start the rot and then freeze-thaw damage causes whole chunks to fall. This is how bridges are adversely affected by chloride based and corrosive deicers.

The key to managing complaints about concrete damage is to avoid becoming entrapped by it. Survey the property carefully and look for areas of new concrete, or places where concrete is obviously susceptible to damage; areas that have new concrete, replaced and/or repaired areas are all going to be more likely to suffer from the freeze-thaw spalling damage until the concrete is at least two years old. After that, it’s a matter of the quality of the concrete and installation that will play a significant role in whether or not it shows damage. Applying a sealer to new concrete helps a great deal.

The world of concrete sealers has improved a great deal in the past decade or two and often, commercial concrete sealers will ward off any opportunity for spalling damage in concrete provided they are applied in accordance with the manufacturer instructions.