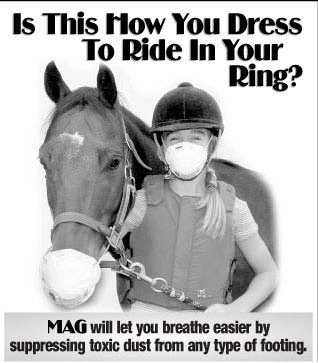

There are an infinite variety of blends of footing materials that are used in indoor equestrian riding arenas. The common problem in all footings is that they start out great but over time quickly develop nuisance dust because the footing is pulverized by the hoof action of constant riding and pounding.

Footing compositions are a very individual thing. Some may prefer a “Palomino” mix of sand and stone dust, while others want a blend of wood, sand, and stone dust, with crumb rubber or chip rubber and sand. There is no limit to the formulas of footings for each individual facility. The common denominator is that over time they all break down, and dust becomes a problem. Even rubber products will break down and eventually become airborne dust particles. Hunter Jumper arenas want footings that are firm but cushy while dressage arenas want a highly consistent footing with about 2-3 inches of loose footing on the surface. Each of these materials presents different potential dust problems.

The US Department of Labor has some staggering statistics about the ill effects of dust and respiratory illnesses caused by it. Nearly every riding arena has sand of some type somewhere in it; either as part of the subsurface or base, or as part of the footing itself. Sand contains silica, an OSHA listed human lung carcinogen, exposure to which leads to silicosis, an incurable lung disease that is caused by inhalation of airborne silica, or sand. Wood fibers also are a very real lung health problem. Consider that when the maximum permissible dust levels in the average woodshop are exceeded, OSHA or local health authorities are not only permitted but are required by law to shut down the facility until the dust is mitigated. Most arena owners are oblivious to the fact that they might be violating air quality laws.

While there are many sources of dust, all dust is the result of the material becoming so finely pulverized that it can become airborne and consequently inhaled. The easiest way to mitigate dust problems is with the addition of water to weigh down the fine particles and prevent them from floating in air.

Water is a viable solution (pun intended) for dust problems in many areas, but it does not come without costs. You must have the water or purchase it, then dispense it with a sprinkler system, and then that sprinkler system must be maintained, which means pumps, pipes, hoses, and potential plumbing problems.

Enter MAG, a proven humectant or hygroscopic agent that draws in moisture naturally. MAG is an ultra pure form of magnesium chloride that is harvested from the Dead Sea, a source of life giving minerals. MAG will draw in water and then hold it at an impressive rate. One pound of MAG can hold up to four times its weight in water under ideal conditions. MAG will draw in moisture continuously and indefinitely and suppress dust permanently in any type of footing in any indoor arena.

Applying MAG to an indoor ring is all art and a little science. Recognizing that footings are very individual, the objective in all footings is to maintain a consistent level of loose material to provide the desired amount of give.

The worst thing that you can do when using MAG is to water your ring. Once you commit to using MAG, it is very important that all watering for dust control is halted following the first application. The reason is simple: You are applying a dust control agent at the surface, and gravity and hoof action will help it to penetrate the footing, coat all the particles of footing and hold them down on the arena floor where you want them. By watering after you have applied MAG, you are rinsing the product off the top and into the subsurface.

The amount needed varies depending upon the size of your ring, the footing composition, and depth, but generally speaking we find that the average indoor arena will need 2 to 4 pallets of our MAG to achieve complete dust stabilization and freeze-proofing in the average 75’ x 150’ indoor with all sand footing. Once the ring is completely stabilized you NEVER need to water again. In fact, watering the ring after it is stabilized with MAG is counterproductive and rinses the MAG down into the base away from the surface where dust emanates. Typically, a maintenance dose of 25% of the initial stabilization quantity is needed annually to cover new dust fines from the footing generated from normal use. Small or private low volume facilities may not need any touching up for years. It all depends on your traffic load and commitment to grooming the surface as well as picking up manure which is a significant source of dust in most arenas.

MAG is very safe to use and handle. The Occupational Safety and Health Administration (OSHA) uses a document called a “Material Safety Data Sheet” (MSDS) to standardize information about all materials. On this form OSHA uses an industry standard for toxicity called an “LD50”, which is the amount of material that is required to kill at least 50% of the test subjects. While this is a morbid thought, it is the standard that the government has established and is recognized industry wide. The LD50 for strychnine, a rat poison, is 16 (milligrams per kilogram of body weight). The LD 50 for aspirin and calcium chloride is 1000 mg/kg. The LD50 for table is salt 3,000, and the LD50 for MAG is 8,100! That means that MAG is 2.5 times less toxic than table salt, is about half as toxic as baking soda and is very comparable to vitamin C, ascorbic acid.

MAG will last forever, or until you wash it away with water or add new footing. If you have high organic materials in your footing, it will absorb the MAG and require more product and more maintenance.

This is the most important part of any successful program; Maintenance. You change the oil in the tractor, the car, and grease and maintain all the other tools of horse management so why wouldn’t you also maintain your riding surface? We recommend that you regularly groom your riding surface with either a tine harrow or other drag-type device which will pull the footing up and turn it over. Even an old piece of chain link fence dragged behind a machine will smooth out and level the riding surface. More often than not, the highest levels of dust are seen when grooming an untreated indoor ring. The best grooming devices are ones which have “teeth” that will dig into the footing and fluff it and turn it over while smoothing it out at the same time.

So, regular grooming is the #1 way to properly maintain your indoor ring once it is treated for dust. Next, a small maintenance dose of MAG to cover new dust fines which develop from on-going use, and, for use around the doorways or problem areas is recommended. The average 100 X 200 indoor ring will take three pallets of MAG to fully stabilize and then one pallet of MAG per year to maintain. Compare these costs to the costs of a sprinkler system and frozen footing in the winter.

There is a side benefit to MAG stabilization that has not been mentioned: freeze proofing your ring. You will never again be forced to shut down in winter because the water saturated footing in your indoor froze up, and you could not ride in it because it is like a frozen moonscape. MAG will keep the same consistency in your footing throughout the year including those sub-zero days when you were not able to ride because the indoor was hard as a stone.

No! MAG is not a liquid; it’s dry flake form! Recently, others have begun to try to capitalize on the enormous success of our MAG. Some companies now offer a modified liquid product which appears to be a blend of unknown waste corn or agricultural chemicals and claimed to be mixed with an unknown source of magnesium. Do not be mislead by others claiming to offer the performance of our MAG in liquid form. It’s impossible to have the same performance of a dry product in liquid form, even if you were to liquefy MAG and then mix it with something else. Only MAG offers our absolute performance guarantee for dust control in your footing.

ONLY MAG products have the benefit of experience of more than 20 years of use in Europe and New England. These unknown liquids are new to the market, are unproven, and there is NO TOXICOLOGICAL DATA on them as to long term effects on equine health in legs and hooves over a long period of time. Know what you are buying. Our MAG is guaranteed to be 100% MgCl2, hexahydrate while liquids chemically cannot contain more than 33% MgCl2,. There are NO agricultural or distiller’s waste products in MAG; it is a pure natural product that is extracted from the Dead Sea – a source of life giving minerals. The costs of these liquids seem to average $0.15-$0.30/ft2, which is equal to about $2000 per treatment and $3000 per year on the average indoor. That is more than five times as expensive as MAG! Don’t be fooled by impostors who are claiming to perform the same as our MAG!

Think of applying MAG to your indoor as though you are fertilizing your lawn. You want to get even, thorough coverage. To do this we recommend the use of a broadcast spreader, or rotary spreader. We have had excellent results using a Brinley 150 lb. spreader that Home Depot sells for less than $200.00. It is mostly plastic with stainless steel knife gate and application adjustments.

Using a rotary spreader, fill the spreader to capacity and begin at the far end of the arena away from the “stockpile” of MAG. Open the spreader up to full capacity (wide open) and then begin by making a checkerboard pattern going first north and south in your arena and then east and west over the same area in a checkerboard pattern. When MAG is properly applied, it will look like it just snowed a light snow in the indoor. You will immediately see MAG start to pull in moisture and dissolve into the footing. This is what it’s supposed to do and what will control dust. Contact us for an analysis on your footing to determine how much product is needed for your particular conditions. Don’t try to go it alone.

To determine your square yards, take the width times the length divided by 9. See the example below:

100’ wide times 200’ long = 20,000 square feet

20,000 square feet divided by 9 = 2,222 square yards

Realize that a treated ring needs some time to equilibrate or settle. While the first day after the first treatment you may think that you are all set, we find that a week or two later dust may begin to break through a little as the fines underneath the surface begin to work up and need to be treated. Typically a small maintenance dose of MAG is required from time to time to suppress new fines as they develop in normal ring use and around doorways and entries where rain may wash away some of the treatment, or where dirt and other sources of dust are dragged in to the arena.

Getting a proper analysis by one of our trained experts is vital to successful MAG use. Footings which contain high levels of organic materials will require more MAG to stabilize than arenas that are 100% mineral such as sand, blue stone, stone dust, etc. Organic materials which we see in arena footings are things like loam, sawdust, bark mulch, shavings, manure, hay dust (do you store hay in your indoor?), and many natural fibers along with some synthetic fibers. Some ground up “waste rubber” additives can contain materials that are capillary and porous adding to the amount of dust abatement material you’ll need. No matter what you are using for dust control, if you have organic materials in your footing the amount of any dust suppressant will be higher because these materials will suck up any dust suppressant that is added to the footing; water, mineral oil, MAG, or some of polymer additives that are out there. Armed with this knowledge, it is helpful to carefully evaluate your footing by looking at it closely for signs that it might contain some of these organic materials.

No two footings are alike!

A burn test on collected samples of the dust itself is the easiest method to determine if your dust is emanating from the mineral (sand) portion of your footing, or, if it is organically derived. The footings analysis expert will instruct you if we feel a burn test is appropriate.

Be aware that when we are asked to stabilize footings with high levels of organic material components, it is expected and likely that it will take much more MAG to stabilize. In fact, in some cases we’ve found that it can 3-5 times as much MAG to stabilize high levels of organic based footing materials than it will mineral based footing materials. That is true of any dust control material used whether its mineral oil, polymer, water, or our MAG. Organic materials like hay and wood are capillary and sponge like, so they will absorb exponentially more treatment (and if using water it will evaporate much more quickly too) and this is why it is vital that you consult with one of our footings experts to run an analysis on your footing to determine how much it will take. When you work with one of our experts, it also ensures our 100% satisfaction or money back guarantee.

Here’s an image of footing that was indicated by the barn owner to be all sand, but when we looked at it under the stereo microscope, you can see quite a bit of organic matter in it; grasses, hay dust, manure, etc.

As you can imagine, if we are treating the footing for all sand dust and it is filled with organic matter like hay shards, manure, and dirt, then the amount of MAG necessary to treat this footing will be exponentially higher than what it would take if the entire footing were only the small white sand particles that you can see.

Understanding the composition of your footing, and more importantly the source of the dust, is a critical component to managing the dust no matter what you are using for dust control. Think of MAG as a dry form of water and add it until the footing is dust free, and the weight, dampness, and consistency you want for your type of riding.

GGT, also called German Geo Textile, seems to be a broadly used term for a footings additive that is a fibrous material. We have heard from some users who indicated that the sellers of these new textile additive materials are advising they need to maintain moisture levels in the range of 10-12% for optimal performance. We do not make any claims nor warranties about using MAG with GGT at those levels. Our MAG is intended to be used ONLY as suggested by the results of our trained professional’s analysis of footing to stabilize for dust and to freeze-proof the footing. Maintaining these high levels of moisture by using our MAG is not recommended and exceeds our comfort level. Please discuss your expectations and options for dust control and freeze-proofing your GGT arena with our representative during the footings analysis to avoid disappointments.

Ask for our brochure to understand more about this extremely safe and proven dust control product.

Packaged in heat sealed 50 lb. poly bags – 48 bags per pallet.:

Easily applied using a tow behind broadcast spreader

When properly applied, it will look like it just snowed lightly on the indoor.

The photo below shows some flakes that were thrown over on to the cement aisle floor have already begun to draw in moisture and dissolve. This is how MAG works to coat dust particles and hold them down on the arena floor.

Initial treatment of a ring should look like this following application.

Within 24 hours, the MAG will dissolve and will wet the ring surface down. This will continue to improve and penetrate the footing as hoof traffic and use drives the product into the footing.

MAG Care and Feeding for Dust Control is available in PDF form for distributing and printing.